What is a skiving machine? Also known as a bell knife skiver or a beveller, a skiver is a kind of machine that reduces the thickness of a piece of leather by cutting a slice out of the leather’s edge. This edge is made thinner than the rest of the leather so that when it is folded over and sewn it allows you to get a nice finished edge. Imagine a small hem on a skirt or shirt sleeve. That is what a skived and folded leather edge looks like. You can see this on the top edges of handbags and wallets, for example. Belts can be skived to allow the end of the belt to be folded over where the buckle is attached. Skivers are used in the boot making industry and strap goods manufacturing. When two pieces need to butt up against each other, one piece is skived on top and the other piece is skived on the bottom. These overlapping pieces can then be glued together before stitching to make a flat seam.

The leather bell knife skiver is a bowl shaped blade that looks kind of like a bowl turned on its side with the sharpened “rim” of the bowl facing to the operator’s left. This sharp rim is the part of the blade that does the actual cutting. The knife rotates away from the operator and the waste leather ends up falling through a cutout in the table. The blade is sharpened by engaging the built-in sharpener with a clutch lever. The built-in sharpener is a grinding stone which matches the shape on the inside curve of the knife.

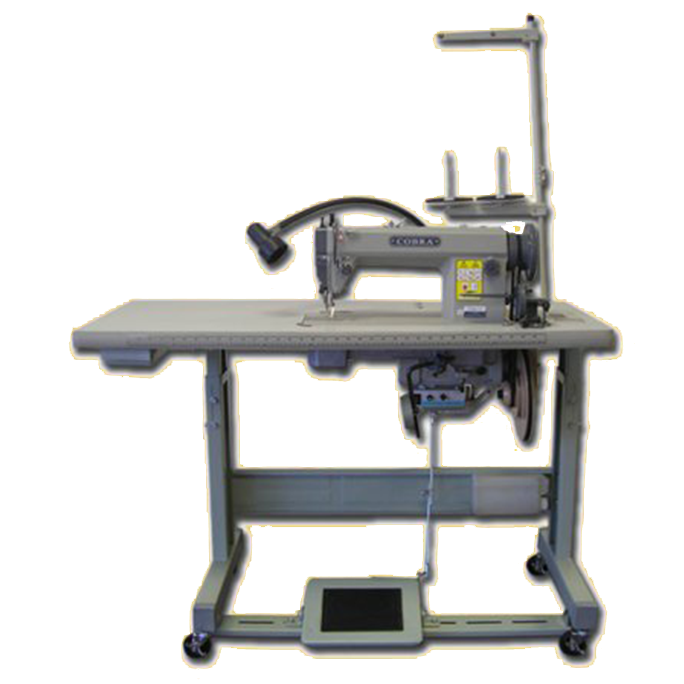

Leather Skiving Machines are very powerful tools to bevel the edges of leather from the lightest weights up to heaviest 14/16 oz. hides. Producing a beautifully smooth and uniform flat or beveled edge is easy as the feed wheel effortlessly pulls the leather through the bell knife. The width, depth and shape of the skiving are easily adjustable by the operator in any amount. You can remove just the roughness from the flesh or hair side, or take off a huge amount and thin out a 1/4” thickness down to as thin as tissue paper.

There are two styles of feed systems on leather edge skiving machines. Some machines have lower feed only for leather up to 12 oz. thickness. Others use both upper and lower feed to accommodate thicker leather, up to 16 oz. The skiving is done by feeding the leather from left to right across the sharp edge of the rotating blade. The width of the skiving is adjusted by moving the back guide (also called a fence) either closer to or farther from the operator. The skiving depth or thickness is adjusted by changing the height of the presser foot which holds down the leather as it is fed through the machine. The shape of the skiving can be changed by replacing the presser feet, e.g. flat, sloped or U-shaped, etc.

As your business grows, so will your product line. You may need many different machines to accommodate the needs of your customers. A successful well-equipped leather shop will be able to produce custom made-to-order leather goods as well as high volume production items.