The density, weight and texture of leather vary. You may have seen videos on the internet that show home machines sewing leather. Although a home machine is able to sew some lightweight leather, it may not be adequate to sew heavy leather. Home machines that are able to sew garment weight leather will not be able to handle the heavier weight leather used for saddles, holsters, tack, belts, or chaps.

Machines offered for sale on the internet that are listed as “industrial strength sewing machine” may say they are 100% metal. They may have small but powerful motors attached. They may sew a couple of layers of 2 oz. leather. Can they use nylon thread? Sure, but nothing heavier than size 69. Can the leather feed smoothly as it is sewn? Yes, as long as it is no more than 1/8th inch thick.

The pressure from the presser foot must be reduced significantly to feed chrome tanned leather evenly. The presser foot applies pressure on top of the material to prevent the material from moving between stitches and to prevent the needle from lifting it. Machines can skip stitches when the thread loop is not formed because the material “flags”, meaning the presser foot’s downward pressure is not sufficient and the needle lifts the material. The thread in the needle’s eye must form a loop for the point of the hook to pass through.

To solve the problems in feeding heavy materials, sewing machine companies make special presser feet. Replacement feet are sold by dealers that are made of Teflon or with little rollers that feed better than the standard steel feet. Others sell roller feet sets, comprised of the needle plate, feed dog and foot that are all replaced together. You may also see devices called walking-foot attachments. These will not transform your machine into a walking foot machine. They only attempt to improve the feeding ability. It’s still the wrong machine for the job. A walking foot attachment will allow the fabric to feed without getting stuck to the foot, allowing the pressure to be increased to avoid skipped stitches, uneven stitch length or the material being lifted. If you are sewing material that is heavy, the machine will not feed it without difficulty, in spite of having the attachment. With no teeth on the underside of the foot material can slip just from the material’s own weight.

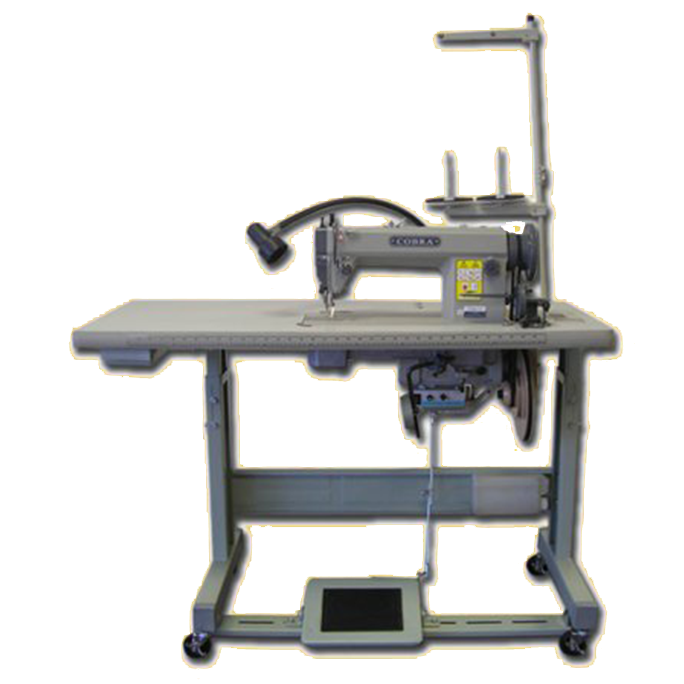

To sew heavy leather you need a real industrial walking foot sewing machine. The thickness of material that an “industrial strength” sewing machine can sew is limited, also the size of needles and thread it can use. For small vinyl projects or lightweight leather vests #69 nylon thread is fine, but it is too light for anything thicker, like belts, bags, chaps or leather upholstery. You will need to use at least #138 size thread for these projects. Many industrial machines cannot use #138 or heavier nylon thread.

As your business grows, so will your product line. You may need many different machines to accommodate your customers needs. A successful well-equipped leather shop will be able to produce custom made-to-order leather goods as well as high sales volume production items.