Warning: Sewing leather on a machine made for garment fabric could damage your machine!

Purchasing and maintaining equipment is an important part of owning a business because unreliable production will definitely limit your ability to fill orders. This is one reason that the equipment you choose be appropriate for the way you intend to use it. A common mistake made by beginners is trying to use an industrial sewing machine designed for the garment industry to sew leather. Industrial sewing machines which are designed primarily for sewing upholstery fabrics may not be suitable for sewing leather. However, they can be modified for sewing light to medium-weight leather. Heavy or extra heavy leather must be sewn with a sewing machine specifically designed for sewing leather.

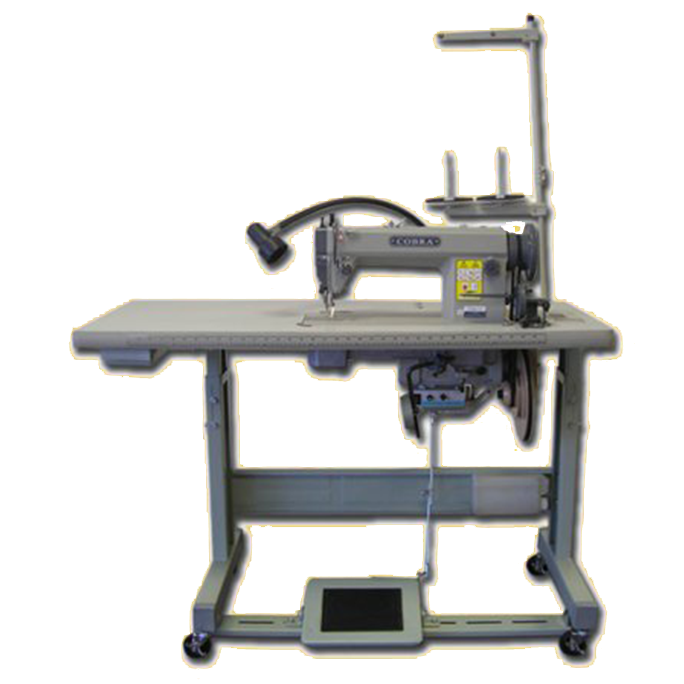

Generally speaking, if you are only going to be making products such as belts, wallets and book covers, etc., then an industrial flatbed sewing machine might be all you need. However, a heavy-duty cylinder-arm machine, instead of a flatbed, is best for sewing the widest variety of leather products due to its versatility. A cylinder-arm (also known as free-arm) sewing machine is indispensable for sewing items with unusual shapes, such as saddles, handbags or jacket sleeves. (Carisoprodol) Machines with an oscillating hook are preferred because this design makes it possible to use a wider range of thread sizes. You can sew anything from lightweight leather to extra heavy leather products.

What should you consider when choosing the best machines for sewing leather products?

Get a machine that is designed for your purpose: First and foremost, be sure to talk to a sewing machine dealer that specializes in industrial leather sewing machines. When choosing a machine for sewing leather it is important that you get one that is designed for leather, especially if you need a reliable jacket sewing machine for thick seams and heavy materials. In other words, be sure that the sewing machine you are thinking of buying will be able to do the job. There is nothing worse than buying a sewing machine and then discovering that it is designed for the boot-making industry when you want to make wallets.

The machine you choose should accommodate a variety of thread sizes: Your decision should take into account the different thread sizes, needle point styles and types of feed mechanisms available on heavy-duty industrial leather sewing machines. The thread sizes range from #69 (for lightweight material) to #346. Size #415 is available but very rarely used. Since leather is not a woven fabric, the proper configuration for sewing leather will include a needle with a special point that pierces or cuts the material rather than a ball-point needle which goes between the weave. The two most common feeding mechanisms are walking foot and needle-feed walking foot (also called compound feed or triple feed). Either style can be used for upholstery fabrics. Many sewing machines used in the boot industry use roller feet, and specialized sewing machines for bag making may also include similar feeding features for durability.

The right drive unit will enable you to sew the heaviest of leather: The sewing machine’s drive unit must be specially designed for sewing leather. The drive unit should include a digital variable-speed DC servo motor and a ball-bearing style speed reducer. The speed reducer serves two functions: first, to slow the sewing machine to a comfortable, easily maneuverable speed and second, to increase the torque for maximum piercing power through the heaviest leather at slow speeds.

A concerned supplier will be able to help guide you through a smart purchase.

As your business grows, so will your product line. You may need many different machines to accommodate your customers needs. A successful well-equipped leather shop will be able to produce custom made-to-order leather goods as well as high sales volume production items.