Cutting leather into precise shapes can be a difficult and time-consuming process, particularly when there is a need to produce dozens of identical pieces. To make this task easier for those in the leatherworking industry, there are a few machines which might interest you. Depending upon the final shape desired, machines like strap cutters, splitters and clickers are used to increase productivity and lower costs. These machines are indispensable to the modern leather goods production facility by lessening time and labor and therefore allowing for reduced costs and increased profits.

• Strap cutters can cut leather strips from 14 inches to less than an eighth of an inch. They operate by using circular blades that slice the leather as it is fed through. By using adjustable spacers between the blades it can be set up to cut multiple widths, for example, 1 inch, 1 ½ inch and 2 inch straps simultaneously. A strap cutter comes in very handy for making fashion products like belts and straps for handbags. They can be used in making various animal restraints like dog collars, harnesses and leashes. People who make equipment for equestrians such as reins and bridles also find them very useful.

• Another very helpful piece of leather cutting machinery is a splitter. This machine has a very sharp blade placed horizontally and rollers that feed the leather through from front to back. A splitter can reduce the thickness of a piece of leather to as thin as 1/64th of an inch. Leather thickness is also measured in ounces, so the heaviest 14-16 oz. leather hides can be split into 2-3 oz., 5-6 oz. or 7-8 oz. weights. This is so a single hide can be used, for example on saddles, where the thicker leather on the seat will match the thinner leather that is used to cover the horn, as well as many other applications.

• The process uses a very large die-cutting leather machine, known in the industry as a clicker, which has a large nylon cutting board and a heavy flattened arm attached to a column behind it. The operator swings the arm out of the way, lays one or more hides on top of the table and places a die resembling a cookie-cutter on top of the hide. These dies are precision-made with a sharp-edged steel band shaped into the desired design. The operator then swings the arm back over the die and presses two buttons, one with the operator’s left hand and the other with the right. The two buttons are separated from each other so both of the operator’s hands are safely away from the cutting surface. The arm, which is driven by hydraulic pressure, comes down onto the die with as much as ten, twenty or one hundred tons of force to cut through the leather. The operator then moves the die or places a different one on the hide, and stamps out another shape until most of the hide is used up.

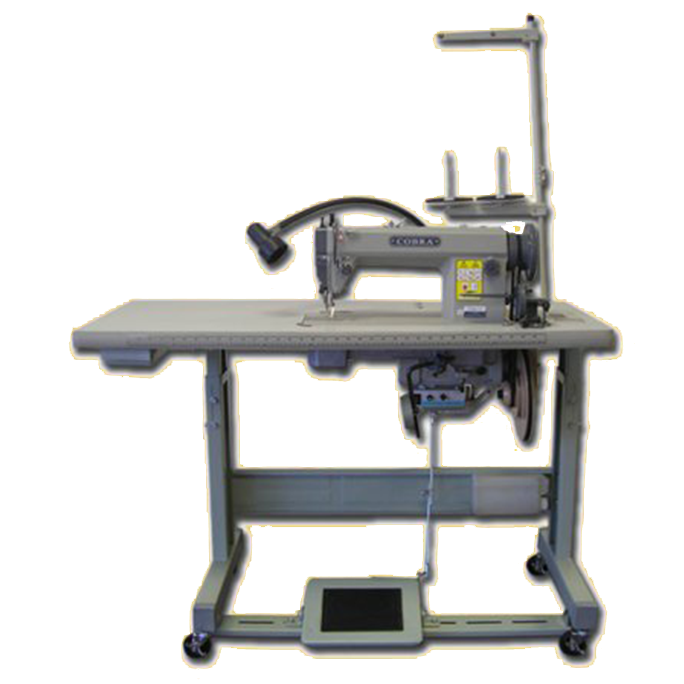

As your business grows, so will your product line. You may need many different machines to accommodate the needs of your customers. A successful well-equipped leather shop will be able to produce custom made-to-order leather goods as well as high volume production items. Visit www.leathermachineco.com or call 866-962-9880 for expert advice on industrial sewing and cutting machines for leather.