Revolutionary Breakthrough! Introducing the new Electronic Positioning System!

Don’t you wish there was an invention that would save you time and money when using your leather sewing machine? Well, your wish has come true. The Electronic Positioning System (EPS) from Leather Machine Co., Inc. is just what you need. The EPS consists of the power hand wheel, the electronic synchronizer and the needle position motor. It’s a labor saving EPS device that saves you time, money and at the same time gives precise and consistent stitching control which is a crucial element for professional looking products. It allows the needle to stop up or stop down, so you can make 90 degree corners, do back-tacking and remove your work without ever having to touch the hand wheel. This also allows you to handle interruptions without showing changes in the stitch. The EPS is especially useful for machines that are known as “long arm” machines, which are used for quilting or saddle making, but they can also be installed on any standard length industrial sewing machine. Most of today’s electronic home machines have this as a built-in feature.

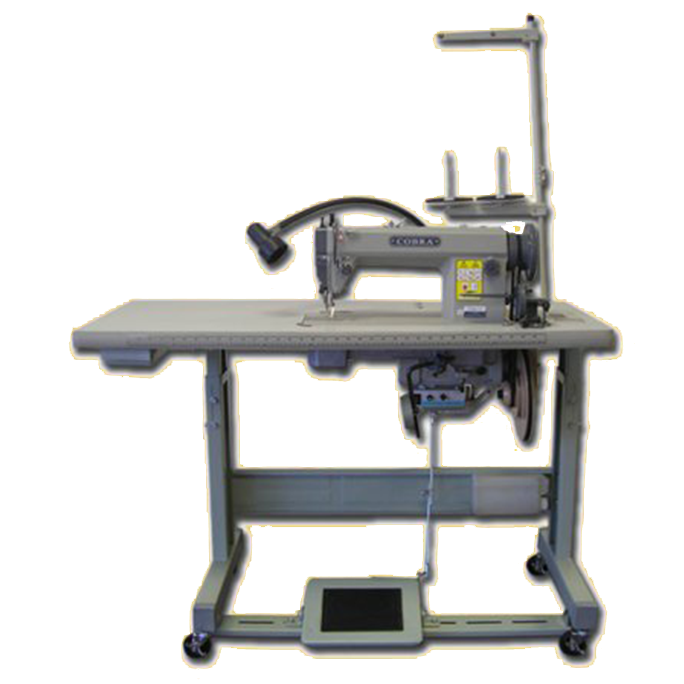

In the past, if you wanted to have this feature on your machine, you would have to purchase an after-market motor and sensor, made by Mitsubishi or Efka, with a cost of up to a thousand dollars. But now, thanks to Leather Machine co., Inc., you can get this extremely useful EPS device installed at less than half the former cost. You can see a demonstration below.

The EPS works by means of the electronic synchronizer which senses the position of the hand wheel as it rotates around its 360 degree cycle. There are two key points in this cycle. The first key point is when the needle has penetrated through the fabric and has come back up just enough for the machine’s hook to catch the loop formed by the thread. The second key point is when the needle and the take-up lever are at their highest points, which is when the stitch cycle is complete. The timing of these two stopping points is set at the factory by an expert mechanic. When you remove your foot from the actuating foot pedal, the sensor on the end of the upper main shaft can tell where the machine’s needle is in the stitch cycle. The needle position motor then advances and stops the machine at the next “needle down” position. The second stopping point, or the “needle up” position, is when the stitch cycle is complete so that you may remove your work from under the presser foot. To get the machine in this position, just push your heel down on the front of the pedal.

By using an Electronic Positioning System you will see increased productivity by reducing training time and operator fatigue. Maintenance is reduced by having less down time due to thread tangling and needle breakage. If you desire to sew one stitch at a time with precise and consistent stitching through very heavy leather, the Electronic Position System, combined with a torque increasing speed reducer, will allow you to accomplish your goal with ease.

As your business grows, so will your product line. You may need many different machines to accommodate the needs of your customers. A successful well-equipped leather shop will be able to produce custom made-to-order leather goods as well as high volume production items. Visit www.leathermachineco.com or call 866-962-9880 for expert advice on industrial sewing machines for leather.